Brake Shoes

UniBond brake shoes are long-lasting, decrease vehicle down-time and lower maintenance costs. Our new brake shoes, when installed with in-spec drums, cams, cam bushings, consistent automatic slack adjusters, and new brake hardware, provide excellent foundation brake balance. Utilizing our shoes will bring the truck to a smooth, steady, safe stop every time.

You’re investing in the most critical safety system on your vehicles…why trust a re-line of unknown quality?

Precise concentricity (matching brake shoe and drum diameter) allows the center of the brake shoe to contact the drum first. This ends cam-biased conditions (initial shoe end contact), provides smooth, vibration-free braking, and improves lining and drum life by as much as 25%.

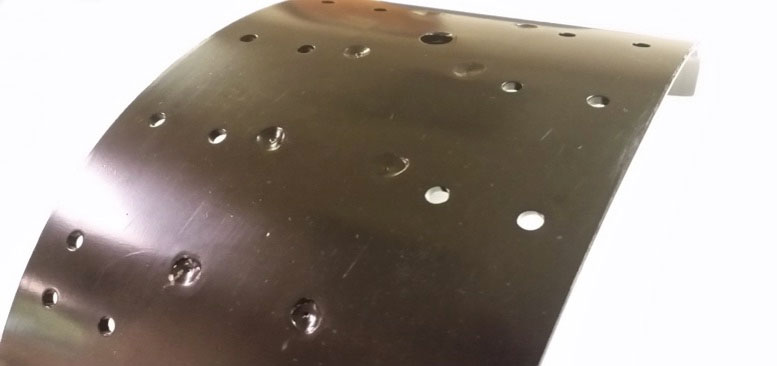

UniBond’s e-coated brake shoes withstand up to 1,000 hours of salt spray testing. This yields more than three times the corrosion resistance of a typical re-lined brake shoe while remaining much more economical than exotic rust prevention coatings. E-coat has been proven to virtually eliminate rust-jacking, saving repair costs and avoiding “out of service” citations. Interested in more details about how the UniBond finish works for you? Click here.

UniBond Brake Shoes:

- Use continuous fillet / seam welded structure – provides structural strength while minimizing distortions due to excess weld heat; avoiding inferior “slot welds” which lack structural strength

- High-grade steel provides a strong structure to meet Federal Motor Vehicle standards and minimize shoe distortion over time (“shoe stretch”)

- By meeting strict dimensional standards, shoes put the brake lining in the optimum “sweet spot” for long lining life

Available Products

| FMSI Number | Axle OEM | Brake System | Diameter | Width | Weight | Construction | hf:att:pa_brake-system | hf:att:pa_diameter | hf:att:pa_width | hf:att:pa_weight | hf:att:pa_construction | hf:att:pa_high-mount |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1308-E | Eaton | E | 15 | 4 | 6.00 | FABRICATED | e | 15 | 4 | 6-00 | fabricated | |

| 1308-Q | Meritor | Q Brake | 15 | 4 | 6.00 | FABRICATED | q-brake | 15 | 4 | 6-00 | fabricated | |

| 1308-T | Meritor | T Brake | 15 | 4 | 6.00 | FABRICATED | t-brake | 15 | 4 | 6-00 | fabricated | |

| 1443-E | Eaton | ES | 15 | 4 | 6.15 | FABRICATED | es | 15 | 4 | 6-15 | fabricated | |

| 1477TT | BPW | Trailer | 420mm | 180mm | 13.00 | FABRICATED | trailer | 420mm | 180mm | 13-00 | fabricated | |

| 4223-E | Eaton | E | 16 1/2 | 5 | 10.20 | FABRICATED | e | 16-5 | 5 | 10-20 | fabricated | |

| 4223-E-HM | Eaton | E | 16 1/2 | 5 | 10.20 | FABRICATED | e | 16-5 | 5 | 10-20 | fabricated | hm |

| 4228-F | Meritor | W Series | 14 1/2 | 6 | 9.40 | FABRICATED | w-series | 14-5 | 6 | 9-40 | fabricated | |

| 4311-E | Eaton | E | 16 1/2 | 7 | 11.04 | FABRICATED | e | 16-5 | 7 | 11-04 | fabricated | |

| 4311-E-HM | Eaton | E | 16 1/2 | 7 | 12.30 | FABRICATED | e | 16-5 | 7 | 12-30 | fabricated | hm |

| 4317-E | Eaton | E | 16 1/2 | 6 | 11.26 | FABRICATED | e | 16-5 | 6 | 11-26 | fabricated | |

| 4317-E-HM | Eaton | E | 16 1/2 | 6 | 11.26 | FABRICATED | e | 16-5 | 6 | 11-26 | fabricated | hm |

| 4398-B | Meritor | W Series | 14 1/2 | 5 | 9.00 | FABRICATED | w-series | 14-5 | 5 | 9-00 | fabricated | |

| 4471-CAST | Meritor | 18 | 7 | 23.73 | CAST | 18 | 7 | 23-73 | cast | |||

| 4504A | Lucas | Wedge | 15 | 6 | 6.47 | FABRICATED | wedge | 15 | 6 | 6-47 | fabricated | |

| 4505M | Lucas | Wedge | 15 | 7 | 7.03 | FABRICATED | wedge | 15 | 7 | 7-03 | fabricated | |

| 4514-EZT-HM-HT | Meritor | Q Brake | 16 1/2 | 6 | 11.25 | FABRICATED | q-brake | 16-5 | 6 | 11-25 | fabricated | |

| 4514-EZT-HT | Meritor | Q Brake | 16 1/2 | 6 | 11.25 | FABRICATED | q-brake | 16-5 | 6 | 11-25 | fabricated | |

| 4514-EZT-U-HT | Meritor | Q Brake | 16 1/2 | 6 | 11.25 | FABRICATED | q-brake | 16-5 | 6 | 11-25 | fabricated | u |

| 4514/4549-C | Meritor | Q Brake | 16 1/2 | 10 | 14.04 | FABRICATED | q-brake | 16-5 | 10 | 14-04 | fabricated | |

| 4514/49-Q | Meritor | Q Brake | 16 1/2 | 5 | 6.80 | FABRICATED | q-brake | 16-5 | 5 | 6-80 | fabricated | |

| 4515-CAST | Meritor | Q Brake | 16 1/2 | 7 | 20.02 | CAST | q-brake | 16-5 | 7 | 20-02 | cast | |

| 4515-ET | Meritor | P Brake | 16 1/2 | 7 | 12.00 | FABRICATED | p-brake | 16-5 | 7 | 12-00 | fabricated | |

| 4515-EZT-HT | Meritor | Q Brake | 16 1/2 | 7 | 12.00 | FABRICATED | q-brake | 16-5 | 7 | 12-00 | fabricated | |

| 4515XEM3-HT | Fruehauf | Q Brake | 16 1/2 | 7 | 12.00 | FABRICATED | q-brake | 16-5 | 7 | 12-00 | fabricated | |

| 4524-ET | Meritor | Q Brake | 16 1/2 | 5 | 10.40 | FABRICATED | q-brake | 16-5 | 5 | 10-40 | fabricated | |

| 4524-EZT-HM-HT | Meritor | Q Brake | 16 1/2 | 5 | 10.40 | FABRICATED | q-brake | 16-5 | 5 | 10-40 | fabricated | hm |

| 4524-EZT-HT | Meritor | Q Brake | 16 1/2 | 5 | 10.40 | FABRICATED | q-brake | 16-5 | 5 | 10-40 | fabricated | |

| 4524-EZT-U-HT | Meritor | Q Brake | 16 1/2 | 5 | 10.40 | FABRICATED | q-brake | 16-5 | 5 | 10-40 | fabricated | u |

| 4528A | Lucas | Wedge | 15 | 5 | 5.47 | FABRICATED | wedge | 15 | 5 | 5-47 | fabricated | |

| 4536-DFC | Dana Spicer | Fast Change | 12 1/4 | 5 1/2 | 6.30 | FABRICATED | fast-change | 12-25 | 5-1-2 | 6-30 | fabricated | |

| 4536-E | Eaton | 12 1/4 | 5 1/2 | 6.30 | FABRICATED | 12-25 | 5-1-2 | 6-30 | fabricated | |||

| 4536-SF | Dana Spicer/ Std Forge | 12 1/4 | 5 1/2 | 6.30 | FABRICATED | 12-25 | 5-1-2 | 6-30 | fabricated | |||

| 4541-B | Meritor | W Series | 14 1/2 | 8 | 12.85 | FABRICATED | w-series | 14-5 | 8 | 12-85 | fabricated | |

| 4551-EZT-HT | Meritor | Q Brake | 16 1/2 | 8 5/8 | 13.25 | FABRICATED | q-brake | 16-5 | 858 | 13-25 | fabricated | |

| 4551-ZFX-LH-LHT/ RH | Fruehauf | Q Brake | 16 1/2 | 8 5/8 | 13.25 | FABRICATED | q-brake | 16-5 | 858 | 13-25 | fabricated | |

| 4552-Q | Meritor | Q Brake | 16 1/2 | 10 | 14.02 | FABRICATED | q-brake | 16-5 | 10 | 14-02 | fabricated | |

| 4591-DXQ | Dexter | 12 1/4 | 7 1/2 | 7.80 | FABRICATED | 12-25 | 7-1-2 | 7-80 | fabricated | |||

| 4591-E | Eaton | 12 1/4 | 7 1/2 | 8.20 | FABRICATED | 12-25 | 7-1-2 | 8-20 | fabricated | |||

| 4591-SF | Dana Spicer | 12 1/4 | 7 1/2 | 7.30 | FABRICATED | 12-25 | 7-1-2 | 7-30 | fabricated | |||

| 4592-ABB | Meritor | Types 1 & 3 | 14 1/2 | 10 | 14.00 | FABRICATED | types-1-and-3 | 14-5 | 10 | 14-00 | fabricated | |

| 4592-ABS | Meritor | Type 2 | 14 1/2 | 10 | 14.00 | FABRICATED | type-2 | 14-5 | 10 | 14-00 | fabricated | |

| 4602-S | Meritor | StopMaster | 15 | 7 | 6.88 | FABRICATED | stopmaster | 15 | 7 | 6-88 | fabricated | |

| 4605 | Meritor | StopMaster | 15 | 6 | 5.80 | FABRICATED | stopmaster | 15 | 6 | 5-80 | fabricated | |

| 4610 | Meritor | StopMaster | 15 | 4 | 14.60 | FABRICATED | stopmaster | 15 | 4 | 14-60 | fabricated | |

| 4656-CAST | MAN | CAM-BRAKE | 410mm | 160mm | 18.00 | CAST | cam-brake | 410mm | 160mm | 18-00 | cast | |

| 4657-CAST | MAN | CAM-BRAKE | 410mm | 220mm | 24.00 | CAST | cam-brake | 410mm | 220mm | 24-00 | cast | |

| 4661-DXQ | Dexter | 12 1/4 | 5 | 6.20 | FABRICATED | 12-25 | 5 | 6-20 | fabricated | |||

| 4661-DXT | Dexter | 12 1/4 | 5 | 6.20 | FABRICATED | 12-25 | 5 | 6-20 | fabricated | |||

| 4670-Q | Meritor | 12 1/4 | 7 1/2 | 7.40 | FABRICATED | 12-25 | 7-1-2 | 7-40 | fabricated | |||

| 4674-E | Eaton | 16 1/2 | 8 5/8 | 13.85 | FABRICATED | 16-5 | 858 | 13-85 | fabricated | |||

| 4692-DFC | Dana Spicer | 12 1/4 | 7 1/2 | 7.30 | FABRICATED | 12-25 | 7-1-2 | 7-30 | fabricated | |||

| 4692-DP | Dana Spicer | 12 1/4 | 7 1/2 | 7.50 | FABRICATED | 12-25 | 7-1-2 | 7-50 | fabricated | |||

| 4692-FC2 | Dana Spicer | FC II | 12 1/4 | 7 1/2 | 8.25 | FABRICATED | fc-ii | 12-25 | 7-1-2 | 8-25 | fabricated | |

| 4692-H | Hendrickson | HXS | 12 1/4 | 7 1/2 | 8.25 | FABRICATED | hxs | 12-25 | 7-1-2 | 8-25 | fabricated | |

| 4693-D | Dana-Bendix | 15 | 4 | 7.00 | FABRICATED | 15 | 4 | 7-00 | fabricated | |||

| 4700-DXQ | Dexter | 12 1/4 | 4 | 5.60 | FABRICATED | 12-25 | 4 | 5-60 | fabricated | |||

| 4700-DXT | Dexter | 12 1/4 | 4 | 5.60 | FABRICATED | 12-25 | 4 | 5-60 | fabricated | |||

| 4702-Q | Meritor | Q Plus | 15 | 4 | 6.80 | FABRICATED | q-plus | 15 | 4 | 6-80 | fabricated | |

| 4703-Q | Meritor | Q Plus | 15 | 5 | 8.44 | FABRICATED | q-plus | 15 | 5 | 8-44 | fabricated | |

| 4704-Q | Meritor | Q Plus | 15 | 6 | 9.12 | FABRICATED | q-plus | 15 | 6 | 9-12 | fabricated | |

| 4705-Q | Meritor | Q Plus | 15 | 7 | 9.71 | FABRICATED | q-plus | 15 | 7 | 9-71 | fabricated | |

| 4707-Q-HM-HT | Meritor | Q Plus | 16 1/2 | 7 | 12.00 | FABRICATED | q-plus | 16-5 | 7 | 12-00 | fabricated | |

| 4707-Q-HT | Meritor | Q Plus | 16 1/2 | 7 | 12.00 | FABRICATED | q-plus | 16-5 | 7 | 12-00 | fabricated | |

| 4707-Q-SD | Meritor | Q Plus Severe | 16 1/2 | 7 | 12.94 | FABRICATED | q-plus-severe | 16-5 | 7 | 12-94 | fabricated | |

| 4708-CAST | Eaton | CAM-BRAKE | 16 1/2 | 7 | 20.63 | CAST | cam-brake | 16-5 | 7 | 20-63 | cast | |

| 4708-ESQ | Eaton | 16 1/2 | 7 | 11.55 | FABRICATED | 16-5 | 7 | 11-55 | fabricated | |||

| 4708-XEM | Eaton | 16 1/2 | 7 1/2 | FABRICATED | 16-5 | 7-1-2 | fabricated | |||||

| 4709 | Eaton | ES (Old Style) | 16 1/2 | 7 | 12.31 | FABRICATED | es-old-style | 16-5 | 7 | 12-31 | fabricated | |

| 4709-E | Eaton | ES II | 16 1/2 | 7 | 12.00 | FABRICATED | es-ii | 16-5 | 7 | 12-00 | fabricated | |

| 4710-Q | Meritor | Q Plus | 15 | 8 5/8 | 11.00 | FABRICATED | q-plus | 15 | 858 | 11-00 | fabricated | |

| 4711-Q-HT | Meritor | Q Plus | 16 1/2 | 8 5/8 | 13.25 | FABRICATED | q-plus | 16-5 | 858 | 13-25 | fabricated | |

| 4715-CAST | Meritor | Cast Plus | 16 1/2 | 6 | 17.48 | CAST | cast-plus | 16-5 | 6 | 17-48 | cast | |

| 4715-Q-HM-HT | Meritor | Q Plus | 16 1/2 | 6 | 11.25 | FABRICATED | q-plus | 16-5 | 6 | 11-25 | fabricated | hm |

| 4716-E | Eaton | Reduced Env. | 15 | 6 | 9.90 | FABRICATED | reduced-env | 15 | 6 | 9-90 | fabricated | |

| 4717-E | Eaton | Reduced Env. | 15 | 8 5/8 | 11.80 | FABRICATED | reduced-env | 15 | 858 | 11-80 | fabricated | |

| 4718-Q-HT | Meritor | Q Plus | 16 1/2 | 8 | 12.50 | FABRICATED | q-plus | 16-5 | 8 | 12-50 | fabricated | |

| 4719-E | Eaton | ES II | 16 1/2 | 5 | 10.40 | FABRICATED | es-ii | 16-5 | 5 | 10-40 | fabricated | |

| 4720-Q-HM-HT | Meritor | Q Plus | 16 1/2 | 5 | 10.00 | FABRICATED | q-plus | 16-5 | 5 | 10-00 | fabricated | hm |

| 4725-E | Eaton | ES II | 16 1/2 | 6 | 11.25 | FABRICATED | es-ii | 16-5 | 6 | 11-25 | fabricated | |

| 4726-E | Eaton | ES II | 16 1/2 | 8 5/8 | 13.25 | FABRICATED | es-ii | 16-5 | 858 | 13-25 | fabricated | |

| 4728-CAST | Meritor | Cast Plus | 16 1/2 | 8 5/8 | 23.20 | CAST | cast-plus | 16-5 | 858 | 23-20 | cast | |

| 4729-E | Eaton | ES II | 15 | 4 | 7.75 | FABRICATED | es-ii | 15 | 4 | 7-75 | fabricated |

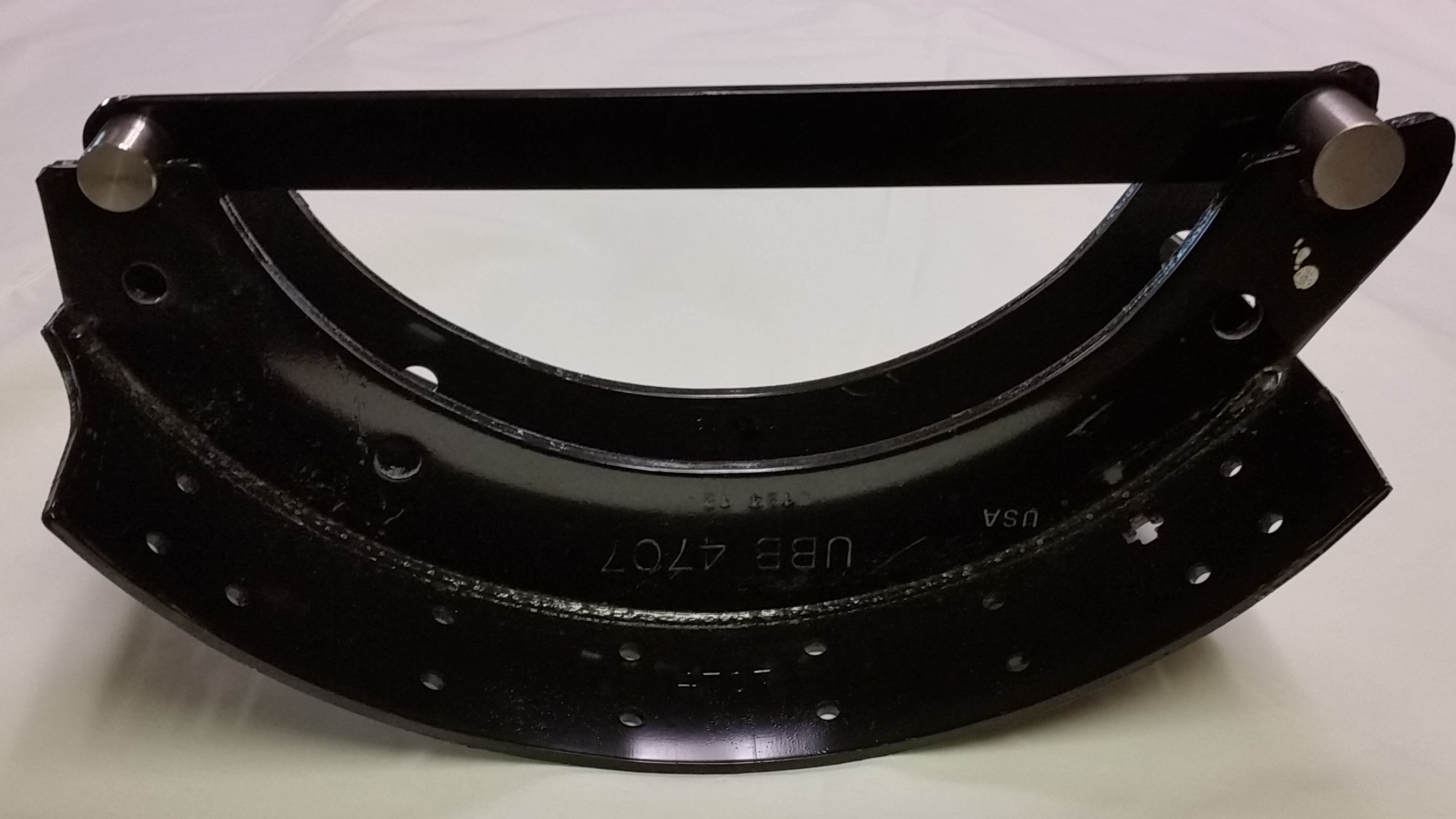

UNIBOND SEVERE DUTY SERIES SHOES

FOR THE MOST DEMANDING DUTY CYCLES

While UniBond’s standard heavy-duty brake shoe will be perfect for the typical line haul vehicle, some heavy-duty trucks demand even more. UniBond’s Severe Duty and cast brake shoes are up to the most demanding challenge.

If your application involves unusual duty, you owe it to yourself to spec the UniBond Severe Duty shoe, along with UniBond’s Severe Duty grade brake hardware.

Severe duty shoes start with the same built-in UniBond quality, then add beefier webs and heavier welds to meet the most demanding conditions. Severe Duty grade hardware complements the shoes, providing heavier anchor pins and increased vibration resistance thanks to premium spring wire and spring processing.

While UniBond’s standard heavy-duty brake shoe will be perfect for the typical line haul vehicle, some heavy-duty trucks demand even more. UniBond’s Severe Duty and cast brake shoes are up to the most demanding challenge.

If your application involves unusual duty, you owe it to yourself to spec the UniBond Severe Duty shoe, along with UniBond’s Severe Duty grade brake hardware.

Severe duty shoes start with the same built-in UniBond quality, then add beefier webs and heavier welds to meet the most demanding conditions. Severe Duty grade hardware complements the shoes, providing heavier anchor pins and increased vibration resistance thanks to premium spring wire and spring processing.

Occasionally brake return springs fail.

UniBond has long experience in the development and production of these springs. We also have an ongoing quality assurance program to ensure satisfactory performance and durability. In recent years, we have responded to customer concerns and undertaken a number of improvement actions. Additionally, we have developed a “Severe Duty” version of our kit for the most demanding applications.

Why do springs fail?

All springs will eventually fail from mechanical fatigue. The spring should be specified, designed and manufactured to provide, with very high confidence, a reasonable service life for the application. The obvious target here is to outlast the brake friction material. Designers think of spring life in terms of total number of cycles (stretches). Return springs for typical over the road trucking are typically spec’ed for 80,000 to 100,000 cycle minimum life. Severe duty springs are rated anywhere from 500,000 to 1,000,000 cycles. When one considers that a busy refuse collection truck may make 1,000 or more service stops a day, this is orders-of-magnitude more difficult service than an on-the-road trucker on interstate highways.

Occasionally brake return springs fail.

UniBond has long experience in the development and production of these springs. We also have an ongoing quality assurance program to ensure satisfactory performance and durability. In recent years, we have responded to customer concerns and undertaken a number of improvement actions. Additionally, we have developed a “Severe Duty” version of our kit for the most demanding applications.

Why do springs fail?

All springs will eventually fail from mechanical fatigue. The spring should be specified, designed and manufactured to provide, with very high confidence, a reasonable service life for the application. The obvious target here is to outlast the brake friction material. Designers think of spring life in terms of total number of cycles (stretches). Return springs for typical over the road trucking are typically spec’ed for 80,000 to 100,000 cycle minimum life. Severe duty springs are rated anywhere from 500,000 to 1,000,000 cycles. When one considers that a busy refuse collection truck may make 1,000 or more service stops a day, this is orders-of-magnitude more difficult service than an on-the-road trucker on interstate highways.

What does a fatigue failure look like?

It may sound counterintuitive, but even when well-manufactured, products will fail consistently. By this we mean that if the product is made to exacting standards, the “weak spot” of the product will always be in the same location. In the case of the return spring, that’s the hook area. The photo to the right illustrates typical fatigue failures. Of course, once the spring fails, it will be tumbled around inside the drum for who knows how long a time. During that time there will be secondary damage to the spring. But the culprit was the original break in the hook.

UniBond sells millions of springs each year; the majority of our sales are for our standard heavy-duty brake kit. A small fraction are severe duty springs. In recent years, we have cut the spring failure rate by more than half through reliability improvements to the standard spring process. For the past two years, recorded failures have occurred at a rate of less than 5 parts per million. This has been accomplished through improvements to our standard duty spring processing, as well as through development of a premium spring for severe duty applications.

Improvements to Standard Spring

In recent years we have also made several improvements across the board to improve our standard kit spring.

- Material handling and storage of spring wire have been improved, including improved packaging and storage on pads, in order to reduce the chances for nicks and scratches in the wire surface.

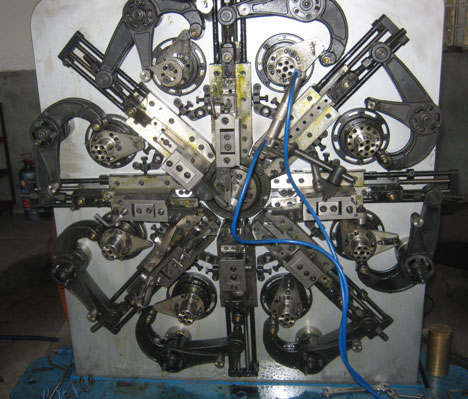

- Spring coiling is done on a new technology computer numeric control (CNC) coiling machine. This reduces the number of operations on the wire and has virtually eliminated “tool marks” on the spring surface. Tool marks provide weak spots where stresses can concentrate and allow failures to begin.

Many competitive shoes – particularly those manufactured in Asia – use a “plug” or “slot” weld. This type of weld is NOT ACCEPTED by the American Welding Society standards, except for temporary “tack” welding. Why? Because the welds don’t provide the structural strength needed.

Many competitive shoes – particularly those manufactured in Asia – use a “plug” or “slot” weld. This type of weld is NOT ACCEPTED by the American Welding Society standards, except for temporary “tack” welding. Why? Because the welds don’t provide the structural strength needed.

This shows a typical tool mark at 5 times actual size. This small indentation can act as a “stress riser”. By replacing our traditional spring forming machines with a computer numeric control spring former, tool marks have been eliminated.

This shows a typical tool mark at 5 times actual size. This small indentation can act as a “stress riser”. By replacing our traditional spring forming machines with a computer numeric control spring former, tool marks have been eliminated.